A few years ago, 3D printing was in its infancy. A neat tool with which people could create scale models of architectural plans or machinery, but not as a means through which you could produce any real components.

As with most technology, however, 3D printing has improved over time. Now, virtually anything can be created with a 3D printer. If you’re looking for an alternative source for heavy duty truck parts, this article is for you.

Here we’ll go over everything you need to know about 3D printing heavy duty truck parts. We’ll discuss the process, the materials required, and whether or not the endeavor is cost effective.

3D Printing Applications

3D printing has been adopting more and more applications in the automotive industry. The burgeoning manufacturing method that is 3D printing is certainly a disruptor in the trucking supply chain.

Recently, major automotive companies have adopted 3D printing technology for the manufacturing of high-end car and truck parts. Recently Ford and HP have been recycling waste materials to use for 3D printing molded car parts.

Aston Martin has developed an active suspension system that can be manufactured fully through 3D printing. Bridgestone has begun 3D printing tire molds to improve traction.

Many of the components of the Bugatti Bolide are 3D printed, and Porsche began demos for fully 3D printed electric vehicles in January of 2021.

3D printing has become a strong player in the automotive manufacturing industry as evidenced by all of the recent adoptions of the manufacturing method by so many large manufacturers.

So can your trucking practice benefit from 3D printing? Let’s go over the details.

The Advantages of 3D Printing Heavy Duty Truck Parts

Let’s take a look at some of the benefits of using 3D printing to manufacture heavy duty truck parts.

Less Manufacturing Labor:

3D printing significantly reduces the amount of labor required to manufacture heavy duty truck parts. Essentially, the machine can do all of the work. All you need to do is have engineers input instructions into the printer and let it do the rest.

This can save millions of dollars over the years as less labor is required to craft detailed truck parts.

Cost Effective Material Usage:

With 3D printers, you can expect to get your bang for your buck with the materials you invest in. 3D printers are flawlessly efficient when it comes to material expenditure.

Every gram of material used through a 3D printer will be used to your exact specifications. Human error is virtually eliminated from the equation when using 3D printing.

Significantly Less Post-Processing Required:

Typically the manufacturing process ends with post-production. This process includes adding the finishing touches to the pieces manufactured, including adding paint, smoothing, and adjusting any defects.

With 3D printing, there is little to no post-production required, as parts can be manufactured to very precise specifications.

Little To No Specialized Tooling Required:

A 3D printer can also be considered a universal tool when it comes to tooling. Specialized jigs, fixtures, molds, gauges, or any other specialized equipment won’t be necessary.

To Create a Supply of Parts that are No Longer Manufactured:

If you have a truck or a buyer with a truck that needs parts that are no longer made, 3D printing can help you immensely.

With the right blueprints, you can produce truck parts that are out of circulation and would otherwise be very difficult to find and expensive to buy. 3D printing essentially makes part scarcity a non-issue.

All of these positives add up to one thing: higher efficiency, and lower costs. The main point of 3D printing is to save manufacturers time and money. For the ultimate consumer, the result is the same.

Whether you manufacture heavy duty truck parts or your business needs a steady supply of them, 3D printing is a solution that will no doubt save you money.

But nothing is perfect, and 3D printing heavy duty truck parts is sure to also have some disadvantages as well. Here are some of the challenges and downsides 3D printing will cause truck part manufacturers and buyers.

The Disadvantages of 3D Printing Truck Parts

Limited Range of Products:

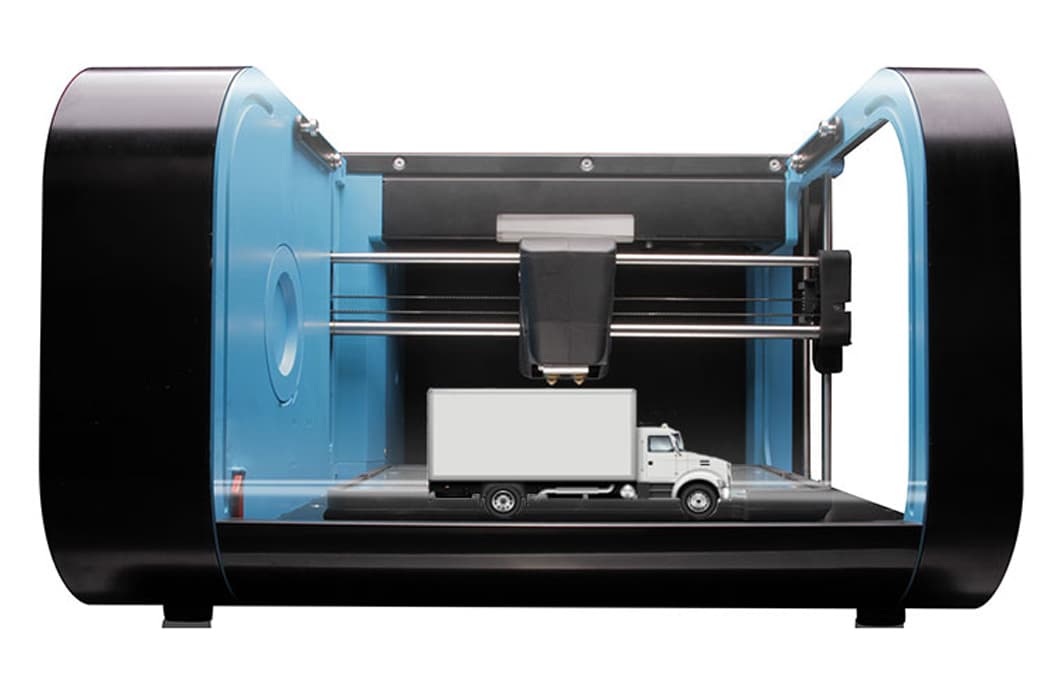

While 3D printers are highly versatile, they are all limited by size. Depending on how large the component you’re trying to manufacture is, the size of your 3D printer may be a limiting factor.

It can be argued that you could manufacture the part by piecemeal, making smaller components of the part until it’s complete; however this is rather complicated and ultimately less efficient than traditional manufacturing.

Compatibility Issues:

3D printers use different materials as substrate through which your desired truck part can be manufactured. Some of these materials, while strong enough to get the job done, have disadvantages. For example, PET-G is strong, however it doesn’t have great chemical and heat resistance.

Scarcity of Material:

Finding a reliable source of the material needed for 3D printing may be difficult, as it is still a relatively new method of manufacturing.

While there are disadvantages, 3D printing is set to be the next big thing in the manufacturing of heavy duty truck parts.